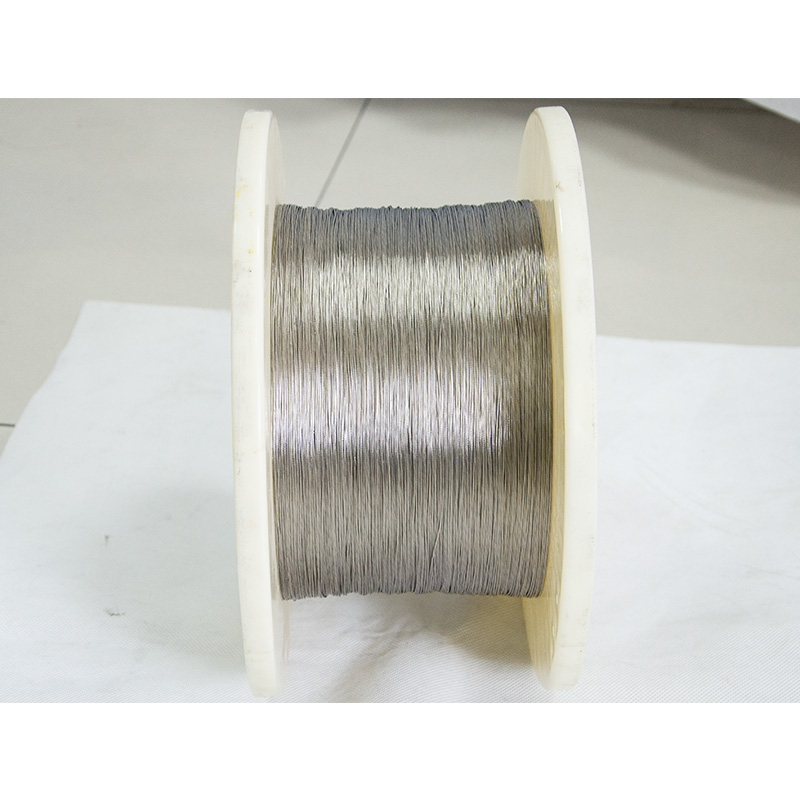

Pretium Fabricatoris Filum NiCr Mixturae Ni35Cr20 ad Elementa Calefactionis

Introductio ad mixturam Nickel et Chromium:

Mixtura Nickel-Chromii magnam resistivitatem, bonas proprietates anti-oxidationis, firmitatem temperaturae altae, stabilitatem formae optimam et facultatem suturae habet. Late adhibetur in materiis elementorum calefactionis electricae, resistoribus, furnis industrialibus, et cetera.

Descriptio accurata:

Gradus: NiCr 35/20 etiam appellatur Chromel D, N4, MWS-610, Stablohm610, Tophet D, Resistohm40, Alloy A, MWS-650, Stablohm 610,

Alia quoque genera filorum resistentiae nichromatici, ut NiCr 70/30, NiCr 60/15, NiCr 60/23, NiCr 37/18, NiCr 35/20, NiCr 35/20, NiCr 25/20, Karma, producimus.

Compositio et Proprietates Chemicae:

| Proprietates/Gradus | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Compositio Chemica Primaria (%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Temperatura Maxima Operativa (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Resistivitas ad 20ºC | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Densitas (g/cm³) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Conductivitas Thermalis | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficiens Expansionis Thermalis (α × 10⁻⁶/ºC) | 18 | 17 | 17 | 19 | 19 | |

| Punctum Liquefactionis (ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongatio (%) | > XX | > XX | > XX | > XX | > XX | |

| Structura Micrographica | austenita | austenita | austenita | austenita | austenita | |

| Proprietas Magnetica | non magneticus | non magneticus | non magneticus | non magneticus | non magneticus | |

Productum: Lamina Nichrome/Taenia Nichrome/Lamina Nichrome/Lamina Nichrome

Gradus: Ni80Cr20/Resistohm 80/Chromel A

Compositio Chemica: Nickel 80%, Chrome 20%

Resistivitas: 1.09 ohm mm²/m

Status: Splendens, Recoctum, Mollis

Superficies: BA, 2B, polita

Dimensiones: Latitudo 1~470mm, Crassitudo 0.005mm~7mm

Producimus etiam NiCr 60/15, NiCr 38/17, NiCr 70/30, NiCr AA, NiCr 60/23, NiFe80, NiFe50, NiFe42, NiFe36, cetera.

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp

-

WeChat

Iuditha

150 0000 2421

-

Summum