Ad situs nostros interretiales salve!

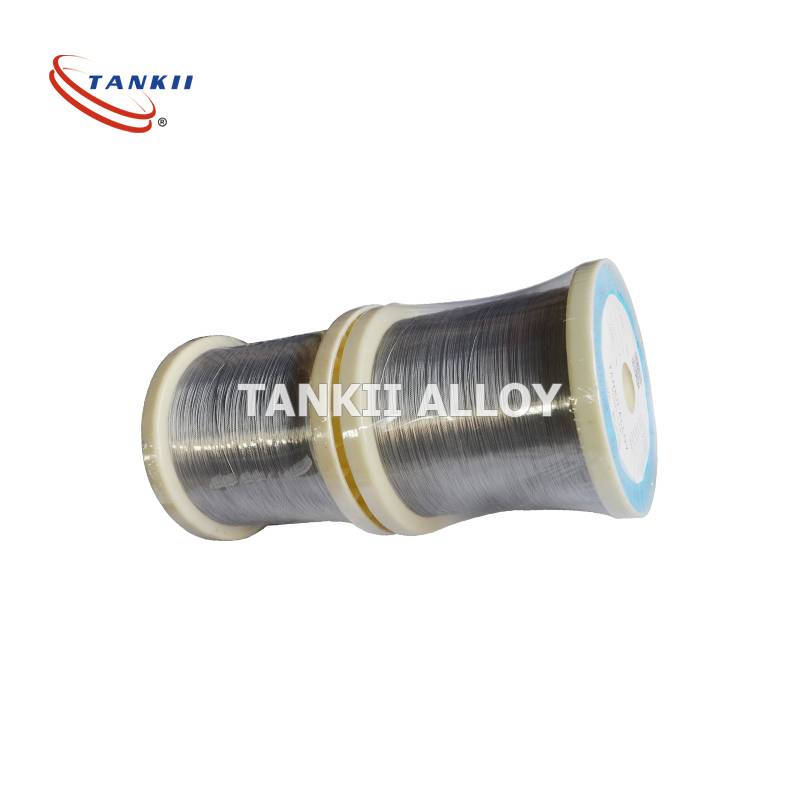

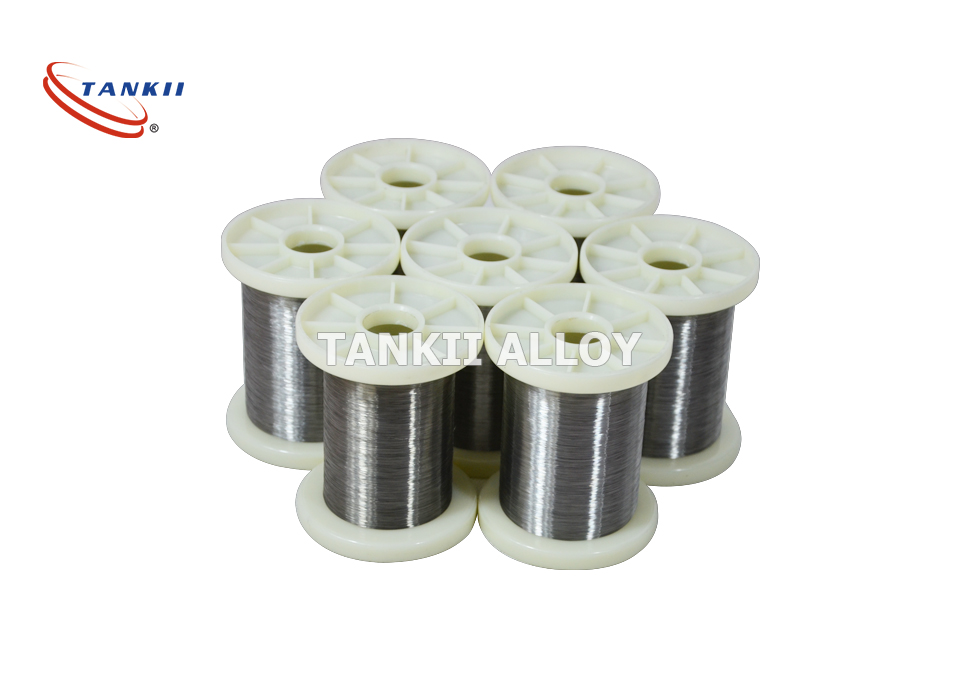

Filum resistentiae electricae calefactionis altae resistentiae ex mixtura metallica 0Cr23Al5 FeCrAl

Descriptio Producti

Mixtura FeCrAl proprietates habet magnae resistentiae, coefficiens resistentiae temperaturae humilis, temperaturae operationis altae, bonae anti-oxidationis et anticorrosionis sub alta temperatura.

Late adhibetur in fornacibus industrialibus, apparatibus domesticis, fornacibus industrialibus, metallurgia, machinis, aeroplanis, autocinetis, militaribus aliisque industriis quae elementa calefacientia et elementa resistentiae producunt.

Late adhibetur in fornacibus industrialibus, apparatibus domesticis, fornacibus industrialibus, metallurgia, machinis, aeroplanis, autocinetis, militaribus aliisque industriis quae elementa calefacientia et elementa resistentiae producunt.

Commodum nostrum: Alta qualitas, breve tempus traditionis, parvus MOQ.

Proprietates: Stabilis effectus; Anti-oxidatio; Resistentia corrosionis; Stabilitas altae temperaturae; Excellens facultas formandi spiras; Conditio superficiei uniformis et pulchra sine maculis.

Usus: Elementa calefactionis resistentiae; Materia in metallurgia; Instrumenta domestica; Fabricatio mechanica et aliae industriae.

Proprietas Praecipua Fili Calefactionis Resistentiae Electricae FeCrAl

Magnitudinis Intervallum:

Filum: 0.018mm-10mm

Virga: 8mm-50mm

Taenia: 0.05*0.2mm-2.0*6.0mm

Taenia: 0.5*5.0mm-5.0*250mm

Filum: 0.018mm-10mm

Virga: 8mm-50mm

Taenia: 0.05*0.2mm-2.0*6.0mm

Taenia: 0.5*5.0mm-5.0*250mm

Materia mixturae

aliae series productorum:

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

Mixtura NiCr: Cr20Ni80, Cr30Ni70, Cr20Ni35, Cr20Ni30, Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Filum welding: ERNiCrMo-3/4/13, ERNiCrFe-3/7, ERNiCr-3/7, ERNiCu-7, ERNi-1, ER70S-6.

Mixtura thermocouple: K, J, E, T, N, S, R, B, KX, JX, EX, TX, NX.

Mixtura Inconel: Inconel 600, 601, 617, X-750, 625, 690, 718, 825.

Mixtura Incoloy: Incoloy 800, 800H, 800HT, 825, 925.

Mixtura Hastelloy: HC-276, C-22, C-4, HB, B/2/3, X, N.

Mixtura Monel: Monel 400, K500.

Mixtura altae temperaturae: A-286, Nimonic 80A/90, GH131, GH1140, GH36, GH2706, GH2901, GH3625, GH3536, GH4169.

Series mixturarum metallicarum praecisionis: 1J33, 3J01, 3J9, 4J29, 4J32, 4J33, Invar36, 4J45, FeNi50.

Mixtura pulveris thermalis: Inconel 625, Ni95Al5, Monel400, 45CT, HC-276, K500, Cr20Ni80.

aliae series productorum:

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

Mixtura NiCr: Cr20Ni80, Cr30Ni70, Cr20Ni35, Cr20Ni30, Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Filum welding: ERNiCrMo-3/4/13, ERNiCrFe-3/7, ERNiCr-3/7, ERNiCu-7, ERNi-1, ER70S-6.

Mixtura thermocouple: K, J, E, T, N, S, R, B, KX, JX, EX, TX, NX.

Mixtura Inconel: Inconel 600, 601, 617, X-750, 625, 690, 718, 825.

Mixtura Incoloy: Incoloy 800, 800H, 800HT, 825, 925.

Mixtura Hastelloy: HC-276, C-22, C-4, HB, B/2/3, X, N.

Mixtura Monel: Monel 400, K500.

Mixtura altae temperaturae: A-286, Nimonic 80A/90, GH131, GH1140, GH36, GH2706, GH2901, GH3625, GH3536, GH4169.

Series mixturarum metallicarum praecisionis: 1J33, 3J01, 3J9, 4J29, 4J32, 4J33, Invar36, 4J45, FeNi50.

Mixtura pulveris thermalis: Inconel 625, Ni95Al5, Monel400, 45CT, HC-276, K500, Cr20Ni80.

Nuntium tuum hic scribe et nobis mitte.

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp

-

WeChat

Iuditha

150 0000 2421

-

Summum