Filum calefactionis electricae altae resistentiae ex mixtura 0Cr19Al3, filum resistentiae FeCrAl

FeCrAl Calefactionis Mixtura 0Cr19Al3

0Cr19Al3

ASTM B603, DIN 17470, JIS C2520, GB/T1234.

Commodum nostrum: Alta qualitas, breve tempus traditionis, parvus MOQ.

Proprietates: Stabilis effectus; Anti-oxidatio; Resistentia corrosionis; Stabilitas altae temperaturae; Excellens facultas formandi spiras; Conditio superficiei uniformis et pulchra sine maculis.

Usus: Elementa calefactionis resistentiae; Materia in metallurgia; Instrumenta domestica; Fabricatio mechanica et aliae industriae.

Proprietas Praecipua Fili Calefactionis Resistentiae Electricae FeCrAl

Magnitudinis Intervallum:

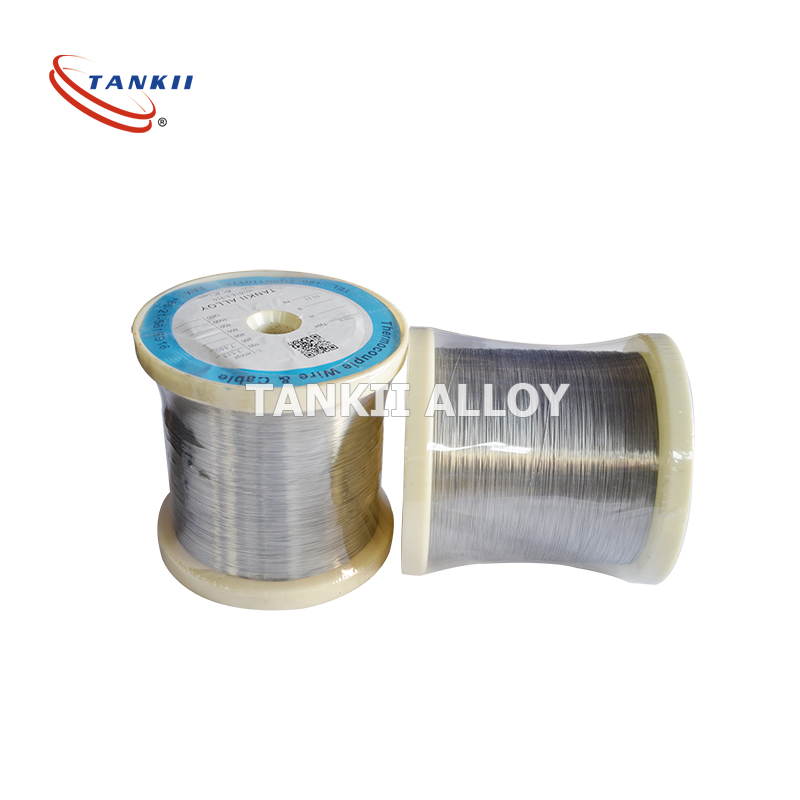

Filum: 0.018mm-10mm

Virga: 8mm-50mm

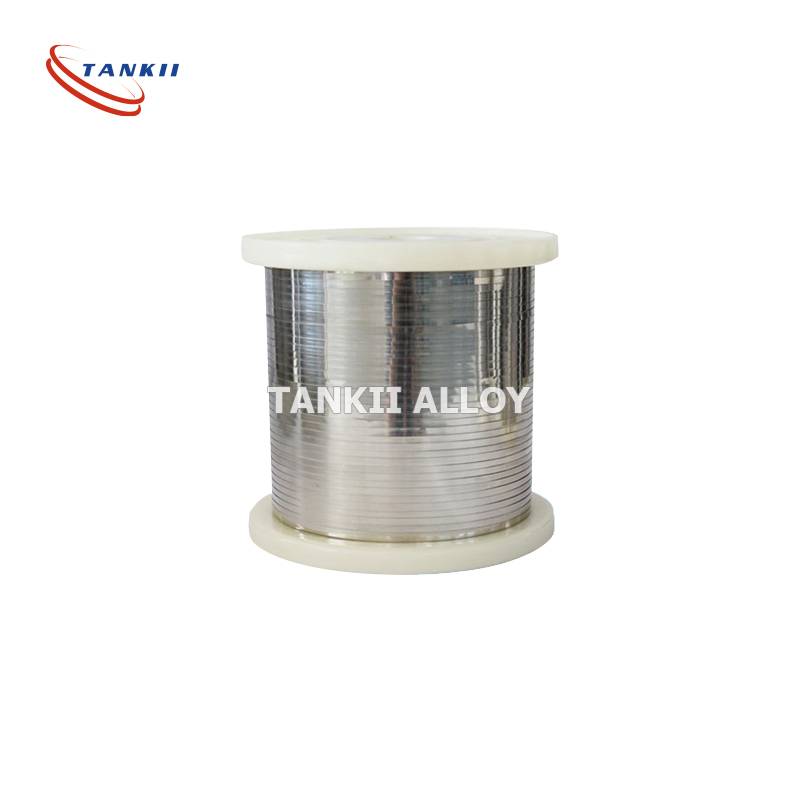

Taenia: 0.05*0.2mm-2.0*6.0mm

Taenia: 0.5*5.0mm-5.0*250mm

| Materia mixturae | Compositio chemica % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | alii | |

| maximum (≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Requies | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Requies | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Requies | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Requies | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Requies | - |

| 1Cr20Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Requies | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Requies | Numerus numericus addendum 0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Requies | |

Aliae series productorum:

Mixtura FeCrAl:OCr15Al5, 1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2.

Mixtura NiCr: Cr20Ni80, Cr30Ni70, Cr20Ni35, Cr20Ni30, Cr15Ni60.

Mixtura CuNi:NC003, NC010, NC012, NC015, NC020, NC025, NC030, NC040, NC050, Constantanus, 6J8/11/12/13/.

Filum ad soldandum:ERNiCrMo-3/4/13, ERNiCrFe-3/7, ERNiCr-3/7, ERNiCu-7, ERNi-1, ER70S-6.

Mixtura thermocouple:K,J,E,T,N,S,R,B,KX,JX,EX,TX,NX.

Mixtura Inconel:Inconel 600, 601, 617, X-750, 625, 690, 718, 825.

Mixtura Incoloy:Incoloy 800, 800H, 800HT, 825, 925.

Hastelloy mixtura:HC-276, C-22, C-4, HB, B/2/3, X, N.

Mixtura Monel:Monel 400, K500.

Mixtura altae temperaturae:A-286, Nimonic80A/90, GH131, GH1140, GH36, GH2706, GH2901, GH3625, GH3536, GH4169.

Series mixturarum praecisionis:1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Mixtura pulveris thermalis:Inconel 625, Ni95Al5, Monel 400, 45CT, HC-276, K500, Cr20Ni80.

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp

-

WeChat

Iuditha

150 0000 2421

-

Summum