Alkrothal 720 No.1 JR Mixtura FeCrAl pro resistore freni

Alkrothal 720 Primus Iuniorpro resistore freni

Usus typici Alkrothal 720 sunt in rheostatis, resistoribus frenandis, et cetera. Etiam ut elementa calefactionis electricae in applicationibus industrialibus adhibetur.

Alkrothal 720 est mixtura ferritica ferro-chromio-aluminii (mixtura FeCrAl) ad usum in temperaturis usque ad 1000°C (1830°F).

Analysis Nominalis

| Cr | Al | Fe |

| 12.0~15.0 | 4.0~6.0 | Aequilibrium |

Proprietates Mechanicae

| Temperatura Maxima Continuae Servitii: Resistivitas 20ºC: Densitas: Conductivitas Thermalis: Coefficiens Expansionis Thermalis: Punctum Liquefactionis: Elongatio: Structura Micrographica: Proprietas Magnetica: | 950ºC 1.25 ohm mm²/m 7.40g/cm³ 52.7 KJ/m·h·ºC 15.4×10-6/ºC (20ºC~1000ºC) 1450ºC Minimum 16% Ferritum magneticus |

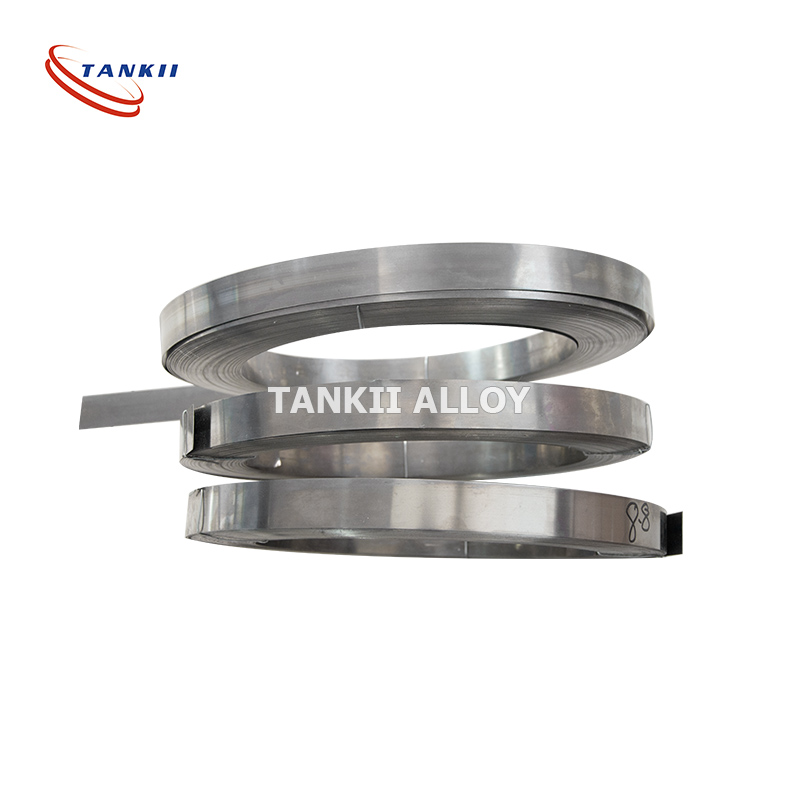

Magnitudo: Crassitudo 0.01-7mm, latitudo 0.5-1000mm

Superficies: BA, 2B

Duritia: Mollis, semidura, dura

Late adhibitum est ut resistor freni magnae potentiae et elementa calefactionis fornacis.

Minus roboris calidi quam mixturae Tophet habet, sed punctum liquefactionis multo altius.

Shanghai TANKII MATERIA Co., Ltd.

PRODUCTOR FECRALIS ET ALCHROMI MISTURARUM IN SINA, PERITISSIMUS IN MUNDO

Infra etiam genera producimus:

0Cr15Al5 et 0Cr19Al3, cetera.

| Compositio Chemica et Proprietas Praecipua Mixtionis Resistentiae Fe-Cr-Al | ||||||||

| Gradus Proprietatum | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Compositio Chemica Primaria (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportunus | opportunus | opportunus | opportunus | opportunus | opportunus | opportunus | |

| Fe | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Temperatura Maxima Continuae Servitii (°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivitas 20°C (Ωmm²/m) | 1.25 ±0.08 | 1.42 ±0.06 | 1.42 ±0.07 | 1.35 ±0.07 | 1.23 ±0.07 | 1.45 ±0.07 | 1.53 ±0.07 | |

| Densitas (g/cm³) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Conductivitas Thermalis | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| (KJ/m@h@oC) | ||||||||

| Coefficiens Expansionis Thermalis (α×10⁻⁶/°C) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Punctum Fusionis Approximatum (°C) | 1450 | 1500 | 1500 | 1500 | 1500 | MDX | MDXX | |

| Robur Tensilis (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | DC-DCCL | 650-800 | 680-830 | |

| Elongatio (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variatio Sectionis | 65-75 | LX-LXXV | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Ratio Contractionis (%) | ||||||||

| Frequentia Flexionis Iteratae (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Duritia (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Tempus Servitii Continui | no | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Structura Micrographica | Ferritum | Ferritum | Ferritum | Ferritum | Ferritum | Ferritum | Ferritum | |

| Proprietas Magnetica | Magneticus | Magneticus | Magneticus | Magneticus | Magneticus | Magneticus | Magneticus | |

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp

-

WeChat

Iuditha

150 0000 2421

-

Summum